P-20+NI 1.2738 & 1.2738 HH Plastic moulding steel

P-20+NI 1.2738 & 1.2738 HH Plastic moulding steel

Specification

(1.2738) Delivered pre hardened ready for use at 280-325 H.B. With added 1%Nickel to ensure consistent hardness through large sections. Easy to polish and readily machinable. Suitable for hard chrome plating and for nitriding.

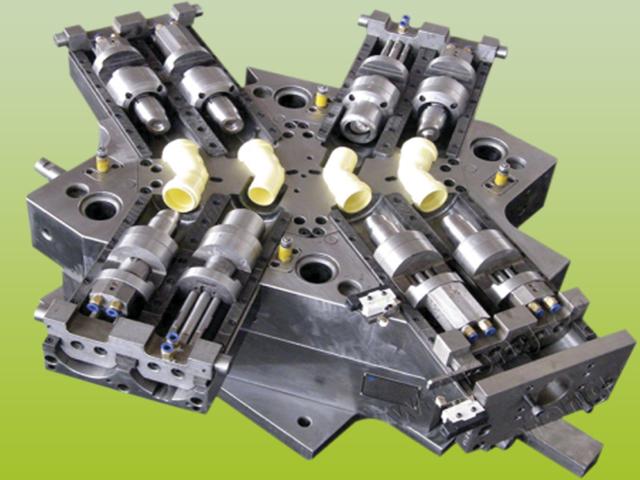

Application

Used for quality for pressing and injection molding tools. If the section exceeds 400mm Having an additional nickel content of 1% increases the hardness. 1.2738 is used in large plastic molds such as container molds, injection molds, deep engraved rubber molds, etc. 1.2738 is a pre-hardened mold steel, which also exhibits high core strength1.2738 is a micro-alloyed, vacuum-degassed steel with the following excellent characteristics: good machinability, excellent polishability, good texture properties.

Chemical Analysis %

| C | Mn | Cr | Si | Mo | P | S | NI |

|---|---|---|---|---|---|---|---|

| 0.35-0.45 | 1.30-1.60 | 1.80-2.10 | 0.20-0.40 | 0.15-0.25 | 0.030 Max | 0.030 Max | 0.90-1.20 |

Hardened and Tempered 280- 325 HB

1.2738 High Hard 360- 400 HB

| Soft Annealing | Cooling | Hardness | Hardening | Quenching | Hardness after quenching HRC |

|---|---|---|---|---|---|

| 710-740°C | Furnace | 235 HB | 840-870°C | Oil or thermal bath cooling, 180-220°c | 52 |

| Tempering°C | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

|---|---|---|---|---|---|---|---|

| HRC | 52 | 50 | 48 | 46 | 42 | 39 | 28 |